Unlocking P&A Success: Collaborative Software Solutions

An oil well has three main phases: Construction; production; decommissioning. One of the steps of decommissioning is Plug and Abandonment (P&A),...

4 min read

Stefan Dinger Aug 8, 2023 9:00:00 AM

Data collection from sensors on down-hole and surface-based equipment is widely used in most oil and gas operations. Wireline or coiled tubing systems collect a range of important data during execution; however, it is often not utilized to its fullest potential. Even though industry professionals are experienced and competent, there are tools available to greatly optimize the execution process utilizing real-time data from your assets.

In this article we will look at some examples of how the utilization of real-time data, through a cloud-based collaborative software solution, can ensure a successful execution, and much more.

The planning stages of an operation attempts to account for most scenarios in advance, with contingency solutions ready to go. If deviations occur, contingencies may have to be implemented. By deviations we mean:

There is a continuous stream of data being collected by sensors on equipment and tools through your rig or platform. You have surface-based sensors on your wireline and coiled tubing units and on high pressure pumps providing data on pressure, temperatures, running speeds, even consumption of energy/fuel and more. Down-hole equipment have their sensors, collecting data through their progression of a specific task.

This is already an established practice in the industry and is seeing increasing amount of automation. However, the scale of sharing this data is minor or underutilized. Streaming of real-time data to a fully integrated software solution is the next step.

Read more: How to Automatically Track and Report all Activities and NPT Events for Wireline Jobs

Decisions must often be made further up the chain of authority. This can be a time-consuming process accounting for the importance of every action and the number of parties involved. It is traditionally an expensive process. Furthermore, having required resources with the correct competency on-site can speed things up, but is mostly not feasible and very costly for operator. This leads to obvious inefficiencies in both down-time of assets, and in the time spent finding the best course of action.

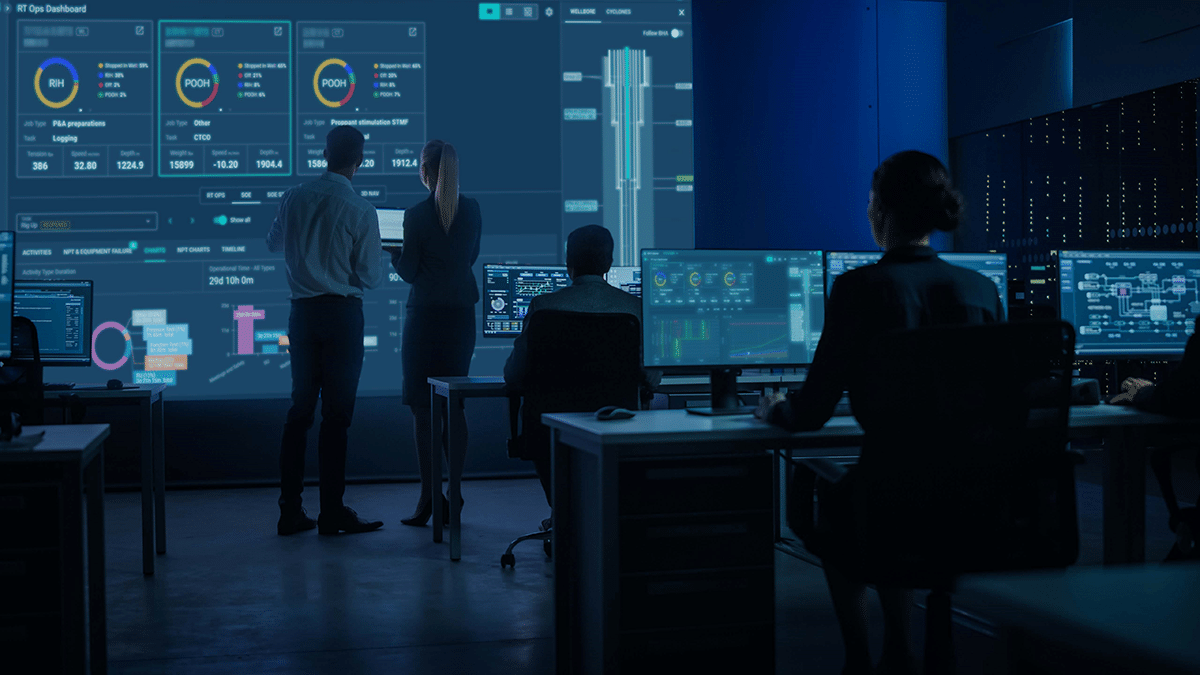

But there are ways of addressing these friction points. Today, real-time data from your operation can be collected, filtered, and inspected on-shore, through a collaborative cloud-based solution.

Data is always collected from an operation, but the general accessibility of this data has been a challenge. Data in raw form is not useful. It must be shared with personnel involved, before it is filtered and interpreted based on industry best practice. This often involves on-land subject matter experts, exploration managers and supervisors.

There are inefficiencies in the time spent on such a problem-solving process. From finding the underlying cause of an issue, to choosing and/or advising on a contingency solution, a lot of time and resources are spent. But that is not the main issue. This approach is often prone to variations of data loss. Without a stringent system of filtering and sharing of the data, a lot is left up to individual interpretation, bias and even misunderstandings. A clear decision-chain and involvement of multiple parties has been a way of mitigating such mistakes. However, without a collaborative software solution, it is an outdated inefficient process.

The solution, and the biggest challenge, has been ensuring that every party, like subject matter experts, managers and other decision makers, are looking at the same holistic view of the situation. Data needs context and structure to be useful. Having the opportunity to personalize how pre-filtered and structured data is accessed and viewed, both increases the foundation of knowledge decisions are made, while revealing possibilities for prediction and de-risking not previously available.

Read more: How to Optimise Well Completion with a Collaborative Software Solution

Any operation, regardless of their data collection abilities, goes through a stringent process of planning and de risking before it is executed. This is based on experience, industry best practices and equipment specifications.

This also involves the geological and industrial history of the field, but historical data does not have to be “old”. Having access to the real-time measurements made only hours, or a few days prior to an incident, facilitates for a faster turn-around on the solution, and even prediction and contingencies of future issue. Steps can be made before having to shut down or damage to assets occur. This improves both HSE and OPEX.

For example, bore conditions may be on the threshold of acceptable parameters, but still within. With sensors continuously feeding data to an integrated cloud solution, you can automatically catch minor changes which affect performance. Relevant personnel and decision makers on land will be notified immediately and/or on-site operators can be advised on the best course of action directly.

Traditionally, this has been a more involved process, where multiple parties must process, interpret and advice retrospectively. With today’s internet infrastructure, even at sea, on-land command centers are a feasible alternative, able to supervise and provide support to multiple operations simultaneously.

This detailed, high-quality, data is also invaluable for future planning and execution of operation, often done through a digital twin. Most production assets already have sensors of variable sophistication in place, but measurements only done for independent closed-loop systems should be considered an underutilized asset and expense.

Read more: What are the Benefits of a Totally Integrated Digital Planning and Execution package?

Regarding the expenses of underutilization of assets, its only by having a detailed overview of your operation in time that you can truly start to optimize. In drilling or intervention operations, the alternative is to have more resources, offshore. With data made available, showing the progress and prognosis until completion have some clear benefits.

With increased efficiency you see a reduction of fuel and energy consumptions, especially in the long-term. This translates to your emissions and environmental impact. With offshore operations spanning decades, there are several metrics that can reveal opportunities of decreased OPEX, while making your operation greener.

Quality assurance and the process of optimizing production now has additional tools available. Put simply, having real-time data accessible for everyone involved is how you do more with less, faster.

Proper utilization of real-time data not only ensure a successful execution but brings a whole range of other benefits in terms of efficiency, emissions and operational expenditure. It can be applied to the execution of most oil and gas operations, but are especially useful for those with a lot of variables and unknowns, like planning, drilling, well intervention and P&A offshore.

In real-time data lies the foundation of more accurate planning, decision making, and reporting/PJA. A single collaborative platform which ensures that everyone is on the same page should not be underestimated, considering the time spent traditionally to reach and complete execution.

Supervisors and decision makers can feel confident that the answers and actions they provide are timely and based on the most up to date information. It allows asking more nuanced questions from data often gathered in dynamic geological systems. It’s not only matter of efficiency, but also of the safety for your crew and assets.

An oil well has three main phases: Construction; production; decommissioning. One of the steps of decommissioning is Plug and Abandonment (P&A),...

Full autonomy is considered the “holy grail” for most industries, including well construction and intervention operations offshore. Coiled tubing and...

Post job analysis (PJA) is the process of consolidating and sharing all of the details from a job, like well intervention and P&A operations. It is...