Levels of Automation in Coiled Tubing & Wireline Operations

Full autonomy is considered the “holy grail” for most industries, including well construction and intervention operations offshore. Coiled tubing and...

4 min read

Christoffer Sørensen May 31, 2023 8:15:00 AM

An oil well has three main phases: Construction; production; decommissioning. One of the steps of decommissioning is Plug and Abandonment (P&A), which is important to ensure that liquids and gas do not leak to the environment after production ends. However, this is a complex undertaking, with traditional methods established before even the internet was commonplace.

In this article we will go through the challenges of P&A operations and how both cost and efficiency can be greatly improved with a collaborative software solution like IDEX.

As mentioned above, at the end of a well's lifetime it needs to be permanent sealed to prevent any environmental issues. The P&A operation involves setting a series of barriers, or plugs, usually made of cement at varying depths of the well. These are installed to isolate the reservoir sections, preventing any leakage to surface. The cement plug barriers are then pressure tested to confirm integrity and parts of the well’s tubing and casing is then cut and retrieved back to surface. It is an operation that involves a lot of different personnel, vendors, equipment, and planning. Additionally, the barriers plugs must be tested in accordance with strict local and international guidelines and regulations.

P&A activity is usually split into two different scopes: A lighter scope and heavy scope. The light scope is aimed at utilizing lower cost units, such as wireline or coiled tubing. The heavier scope usually requires an expensive rig, plus additional contractors, and crew to complete.

A big challenge is that each well is different, with its status somewhat of an unknown, assumptions must be made, and the planning must consider these uncertainties.

Wells can be:

Therefore, a large number of contingencies and «what-ifs» must be planned for to minimize idle time and ensure that both crews and the environment remain safe and secure. With such a large scope, you often rely on a lot of different equipment and service providers who all need to be involved in the planning and execution of a P&A operation.

In order to mitigate these uncertainties, a key part of planning involves looking for historical well data and analysing it. Any evidence of deterioration, scaling or treatment with acids must be considered as these can all impact the state of the well.

Read more: Can Well Intervention Be Digitalized?

All these things add up. The UK alone is spending roughly 1.5b GBP on P&A operations a year, with roughly 150 wells expected to be plugged and abandoned per year, exceeding the number that is drilled. Globally, the number of wells which will see end-of-life the next 10 years is staggering, a number in the tens of thousands. Therefore, anything that we can do to reduce inefficiencies in planning the P&A operations will have a large impact on costs.

Data collection is an important step early in P&A planning. Just as when developing a field, you rarely run isolated P&A operations on a single well in an area. What you discover on the first well, will be a good indicator of what you will find on the next. This should inform and shape your general approach, as any data gap create unknowns, which we fill with assumptions and contingency solutions on stand-by.

These assumptions carry associated risks, which is manageable if recognized early. We must have time to act, eliminating or mitigating, by devising contingencies for these risks. By recognising and consolidating identifiable unknowns early on, we reduce the cost of the avoidable – surely a practice we should all routinely adopt.

Read more: How to Automatically Track and Report all Activities and NPT Events for Wireline Jobs

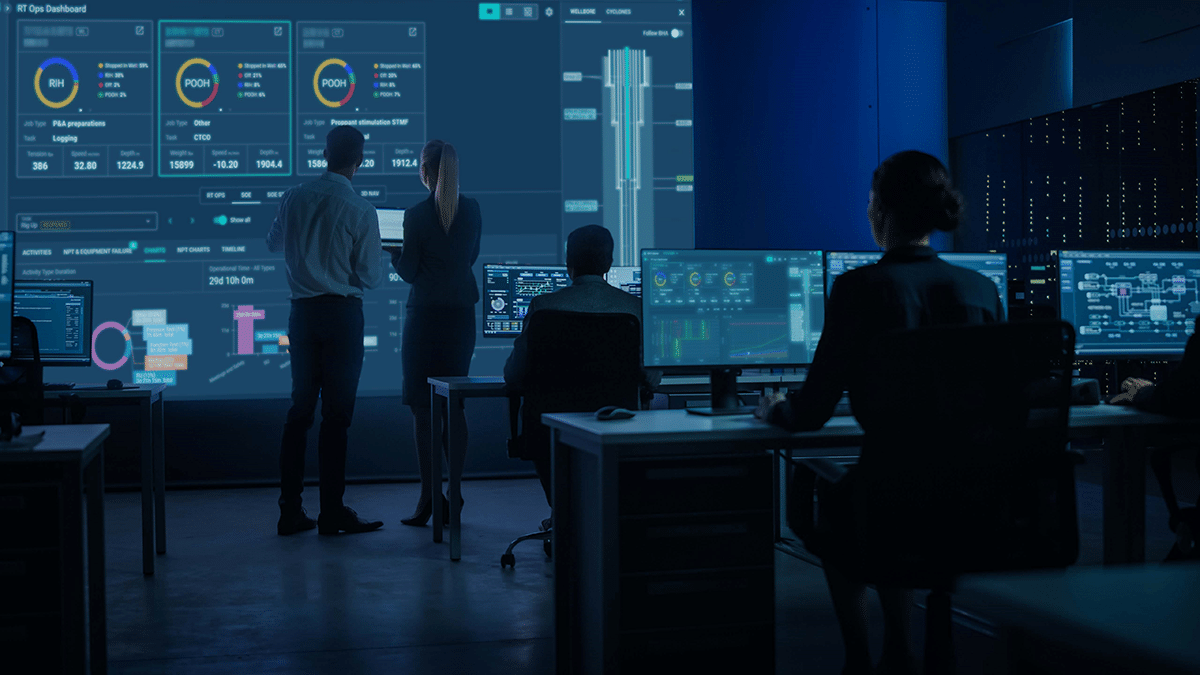

We need a place where you, and everyone collaborating, can access, store, and share information. A cloud-based and real-time solution, where you are sure that what you are working with is the latest version of key data. Reports and notifications should be automatically generated and distributed at any time they are required.

It must be an agile platform, able to quickly adapt to changes and address unplanned events, but always grounded in the most up-to-date and comprehensive data available. In a way, it must be able to learn. Through a continuous improvement cycle, information gathered early on in an operation must be taken advantage of in the next step of the campaign.

With libraries of industry standards, regulations, and guidelines, along with real-time information from your operation, the system gives you the next steps and required actions. This way all parties will automatically be notified of the actions that they must complete along with the relevant information for those actions, reducing the need for coordination meetings dedicated to mere delegation of tasks.

Lastly, it greatly reduces the need for people on-site, further cutting cost, while improving HSE. What used to be a costly logistical challenge of getting supervisors out to rigs and platforms, is now just another day at the office, with the added benefit of more eyes on the target. This is the core of One Digital Well, and collaborative software solutions like IDEX. All data is captured and stored and made available to all of those who need access to it.

Read more: How to optimise well completion with a collaborative software solution

Plug and Abandonment operations are the process of securely sealing off wells which relies on huge amounts of planning. Every well is different due to its age, the technology used down-hole and geological conditions. It’s a very costly process.

The key in ensuring efficient planning of this process is a collaborative software solution that provides a platform for storing, sharing and accessing all information gathered through a well’s lifetime, reducing the need for manual reporting, logistics, on-site crew and much more.

The only way of bringing P&A operations into the 21st century is proper utilization and consolidation of the increasing amount of data we gather. IDEX is one such platform. The heart of One Digital Well.

Full autonomy is considered the “holy grail” for most industries, including well construction and intervention operations offshore. Coiled tubing and...

The lifetime of a well is dependent on where you are in the world – from up to 50 years in Saudi Arabia to 10 years in the North Sea. To secure the...

Data collection from sensors on down-hole and surface-based equipment is widely used in most oil and gas operations. Wireline or coiled tubing...